Concrete Repairs & Restoration

How Lucent can restore different types of damage in steel and concrete

- Inspection by professional and experienced staff, Diagnosis the problem and understand the type of damage mechanism is the backbone to decide the part forward for repair or replacement. Due to huge varieties of chemical repair polymers we have we make the repair mostly possible to save money and time. Equipment to be used to support the inspection and analysis

Rebound Hammer Test

Chemical indicator to test carbonation depth

Rebar Finder

Humidity Tester

CO2 PPM detector

Infrared Thermometer

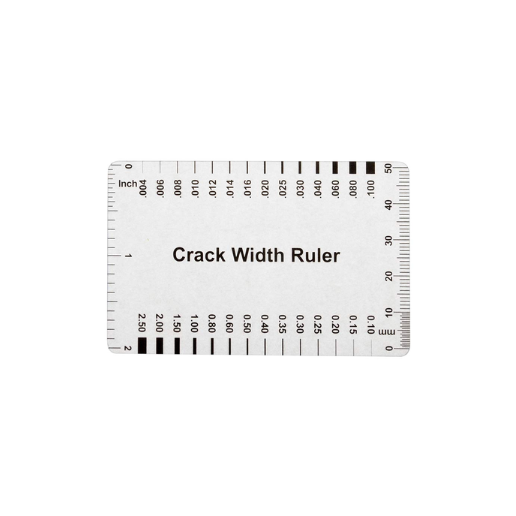

Crack Width Ruler

Surface roughness test

High resolution digital camera

Third Party Laboratory for Testing Materials

Mechanical steel brush for surface preparation pre treatment.

2. Surface preparation and material selection for eligible area for repair. There are bunch of standards industry can be utilized for providing proper surface. For concrete and steel repair/coating which we will abide before any repair such as, ASTM D4417, SSPC-PA17, NACE, ICRI 310.2-9. Our professional Staff are highly experienced to select the proper material for repair.

Corrosion of rebards can be seen under palled concrete mostly due to low quality of concrete which leads to carbonation. Our products for repair can work efficiently here.

Cracks with water leaks which may happen due to concrete shrinkage or settlement. We Provide permanent solution for such cases using polymer injection.

Eroded concrete surface can be seen due to continuous flow of water or sewer. We offer complete surface upgrade with much higher resistance to erosion than concrete.

All types of acid may attack concrete in different levels due to there low PH value.